STUDY RESOURCE

FOR

CERTIFICATE II / III IN ELECTROTECHNOLOGY

ELECTRICIAN / ELECTRICAL FITTER

APPRENTICES

About

This qualification provides individuals with the skills and knowledge to select, install, set up, test, fault find, repair and maintain electrical systems and equipment in buildings and premises. It includes Electrical Regulatory Authority Council (ERAC), or their successor’s, Essential Performance Capabilities for an ‘Unrestricted Electrician’s license’.

Being able to learn how to select, install, set up, test, fault-find, repair and maintain electrical systems and equipment in buildings and premises requires a very specific and complex skillset, which is why qualified and trained people in this industry are always in demand.

UEE33020 (Old 33011) - Certificate III in Electrical Fitting

This qualification provides competencies to manufacture, fit, assemble, erect, operate, test, fault find, alter and repair electrical equipment and includes electrical wiring work only if that work is associated with assembling, maintaining, terminating or altering the wiring between electrical components within a plant or machinery. An electrical fitter is not authorised to install any electrical wiring systems within an electrical installation as prescribed by definitions contained in AS/NZS 3000 Electrical installations (known as the Australian/New Zealand Wiring Rules).. Electrical equipment means any appliance, article, accessory, wire, fitting, cable, conduit or apparatus that generates, uses, conveys or controls (or that is intended to generate, use, convey or control) electricity above extra-low voltage (ELV).

Contact

- Corner Lloyd Street and, Eddie Barron Dr, Midland WA

- 6056

- 0414391548 - Geoff Fielding

- glfieldi@iinet.net.au

- 0800 - 1615

Ready Skills Info

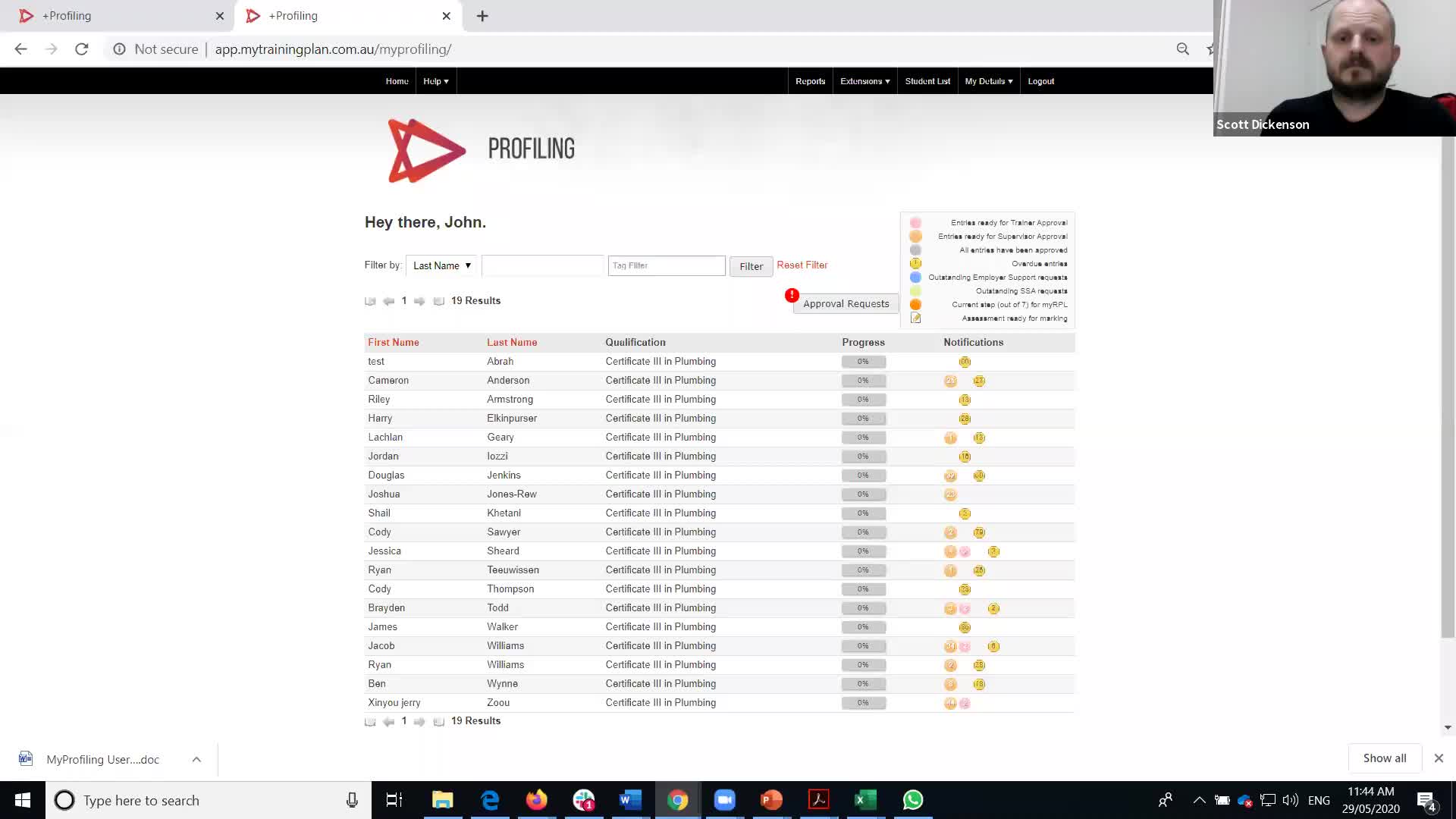

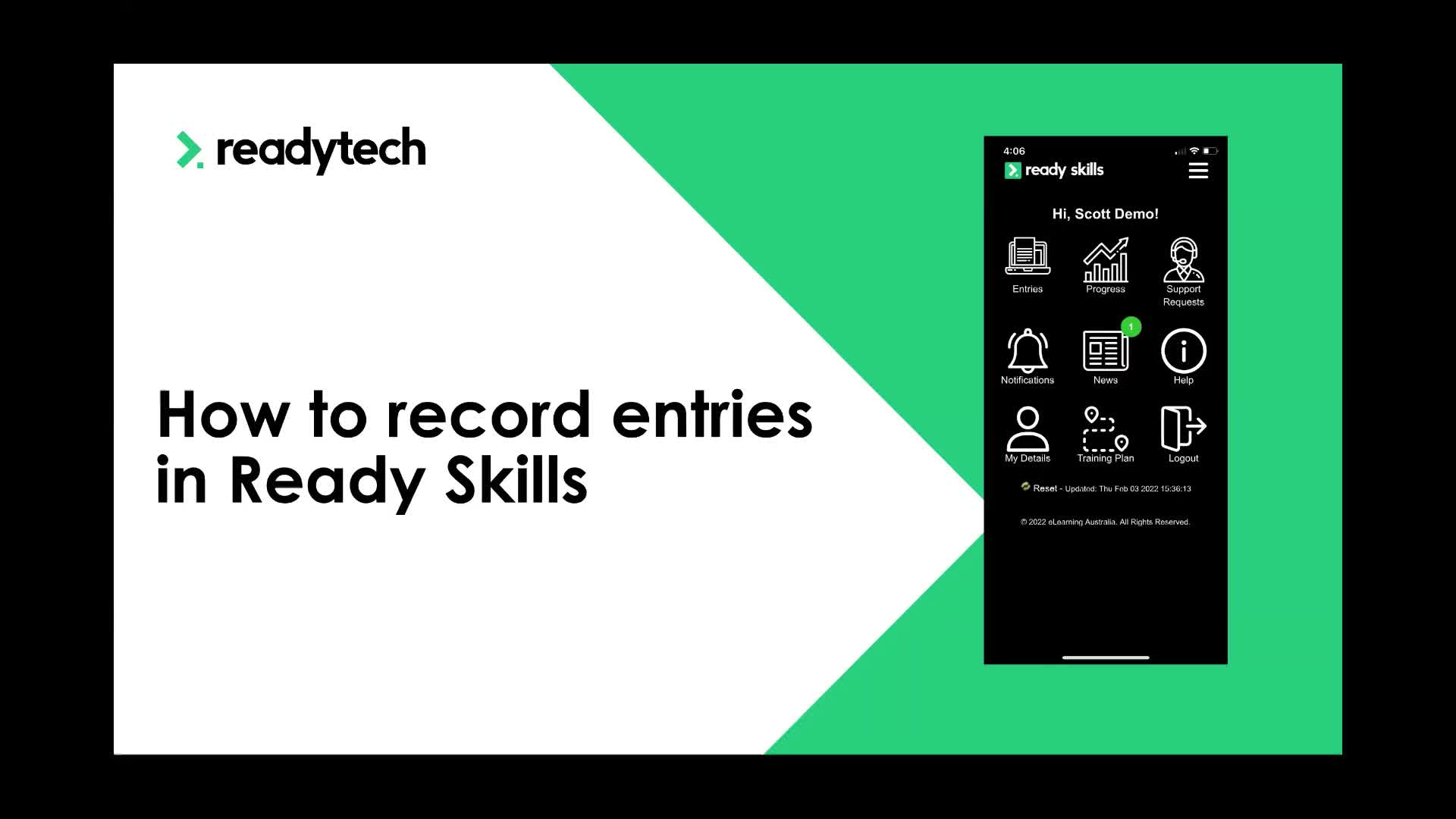

Have a look at these videos which should help you with MY Profile

Read MoreNMTafe Induction

NMTAFE Induction info has links to the important stuff you need to know when starting your journey at NMTAFE, enjoy!

Read MoreCERT II

This unit covers undertaking scheduled routine work activities in the energy sector within an agreed time, to an acceptable quality standard and with a minimum of waste. It encompasses working safely and applying knowledge of carrying out routine work activities in the electro-technology environment.

Read MoreThis unit covers identifying and selecting electronic components for assembly from job specifications. It encompasses working safely, interpreting job specifications, identifying components by colour code and markings and following quality procedures and work instructions.

Read MoreThis unit covers attaching flexible cords and plugs to electrical equipment for connection to supplies up to 230V a.c. This may be incidental to or a primary and regular function of work related to a principle function in the workplace. It encompasses working safely, identifying plug configurations, selecting and using testing and measuring devices, terminating and connecting cords/plugs and conductors, safety testing and reporting.

Read MoreThis unit involves the skills and knowledge required to use routine equipment, plant, technologies and personnel protective equipment (PPE) in an energy sector environment. It includes preparing and using equipment, plant, technologies and PPE, and completing workplace requirements in an energy sector work environment. No licensing, legislative or certification requirements apply to this unit at the time of publication.

Read MoreVETDSS

CPCCWHS1001 - Prepare to work safely in the construction industry

This unit of competency specifies the mandatory work health and safety training required prior to undertaking construction work. The unit requires the person to demonstrate personal awareness and knowledge of health and safety legislative requirements in order to work safely and prevent injury or harm to self and others.

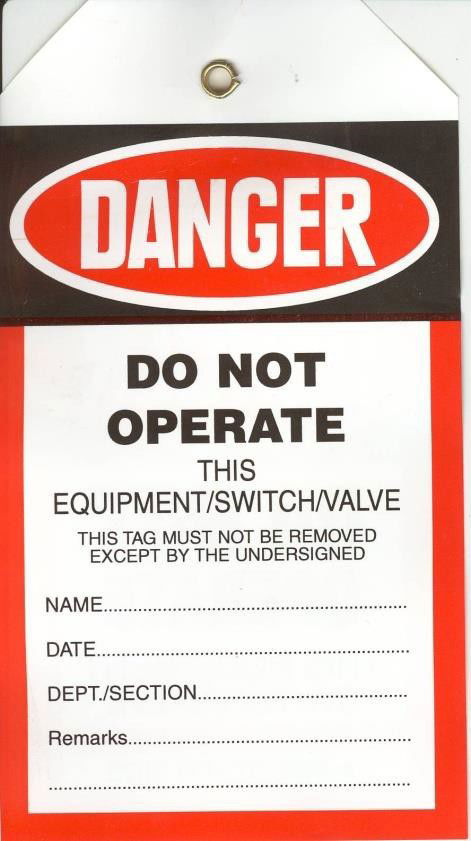

STAGE 1

This unit specifies the mandatory requirements of occupational health and safety and how they apply to the various electrotechnology work functions. It encompasses responsibilities for health and safety, risk management processes at all operative levels and adherence to safety practices as part of the normal way of doing work.

Read MoreThis unit covers the application of industry/enterprise policies in actively participating in work activities and in one's own competency development. It complies with established industry/enterprise procedures regarding how work is conducted, understanding responsibilities and obligations under competency development plan, following activities for developing competency, self-monitoring competency development and meeting trainee obligations for periodic reporting of competency development activities.

Read MoreThis unit covers the basic use of personal computers application relevant to a work function. It encompasses switching the computer on, applying user preferences, selecting basic applications, entering and retrieving information and printing files. This unit applies to all aspects of Electrotechnology – engineering applications only. For general competencies related to Information Technologies refer to the latest endorsed IT Training Package.

Read MoreThis unit covers basic fitting and fabrication techniques as they apply in the various utilities industry work functions. It encompasses the safe use of hand, fixed and portable power tools; cutting, shaping joining and fixing using metallic and non-metallic materials; dismantling and assembling equipment; basic mechanical measurement and marking-out and reading drawings/diagrams.

Read MoreThis unit covers fixing, securing and mounting techniques as apply in the various electrotechnology work functions. It encompasses the safe use of hand and portable power tools, safe lifting techniques, safe use of ladders and elevated platforms and the selection and safe application of fixing devices and supporting accessories/equipment.

Read MoreThis unit covers determining correct operation of single source d.c. series, parallel and series-parallel circuits and providing solutions as they apply to various electrotechnology work functions. It encompasses working safely, problem solving procedures, including the use of voltage, current and resistance measuring devices, providing solutions derived from measurements and calculations to predictable problems in single and multiple path circuits.

Read MoreSTAGE 2

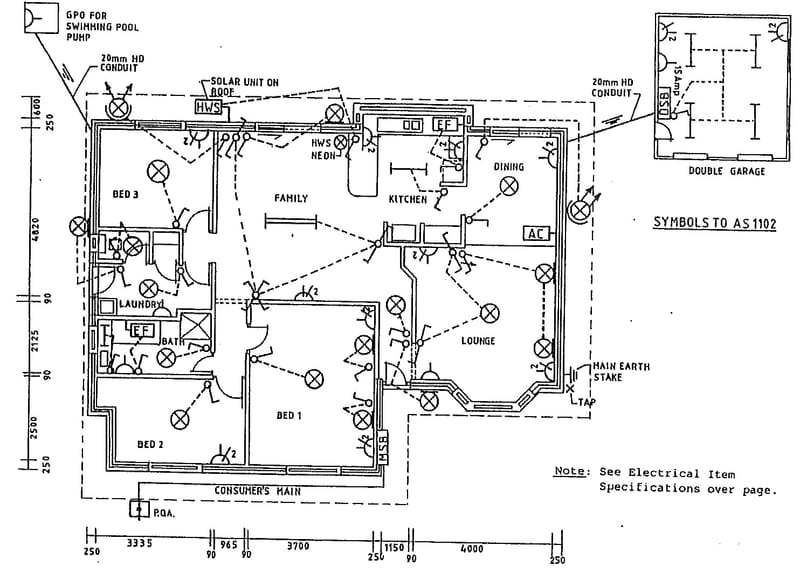

This unit covers the use of drawings, diagrams, cable schedules, standards, codes and specifications as they apply to the various electrotechnology work functions. It encompasses the rudiments for communicating with schematic, wiring and mechanical diagrams and equipment and cable/connection schedules, manuals, site and architectural drawings and plans showing the location of services, apparatus, plant and machinery and understanding the use and format of compliance standards and job specifications

Read MoreThis unit covers the termination of cables and cords and their conductors at accessories and current-using devices designed to operate at voltages up to 1,000 V a.c. or 1,500 V d.c. It encompasses working safely and to standards, understanding wiring system and cable types and applications, selecting appropriate termination accessories, preparing and terminating cables and cords, terminating cables/cord conductors and ensuring completed termination complies with requirements.

Read MoreThis unit covers determining correct operation of electromagnetic devices and related circuits and providing solutions as they apply to electrical installations and equipment. It encompasses working safely, power circuit problems solving processes, including the use of voltage, current and resistance measuring devices, providing solutions derived from measurements and calculations to predictable problems in electromagnetic devices and related circuits.

Read MoreThis competency standard unit requires the worker to undertake methods of work practice that minimises energy and material usage and to seek energy reduction strategies in the energy sector workplace. The unit seeks to minimise negative impacts on the environment.

Read MoreSTAGE 3

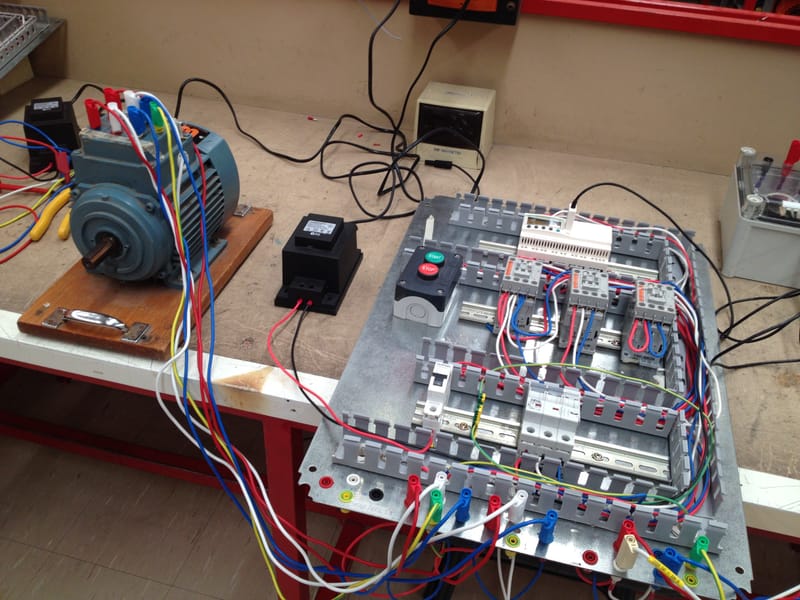

This unit covers ascertaining correct operation of single and three phase a.c. circuits and solving circuit problems as they apply to servicing, fault finding, installation and compliance work functions. It encompasses safe working practices, multiphase circuit arrangements, issues related to protection, power factor and MEN systems and solutions to circuit problems derived from calculated and measured parameters.

Read MoreThis unit covers ascertaining correct operation of single and three phase machines and solving machine problems as they apply to servicing, fault finding, installation and compliance work functions. It encompasses safe working practices, machine connections circuit arrangements, issues related to machine operation, characteristics and protection and solutions to machine problems derived from calculated and measured parameters.

Read MoreSTAGE 4

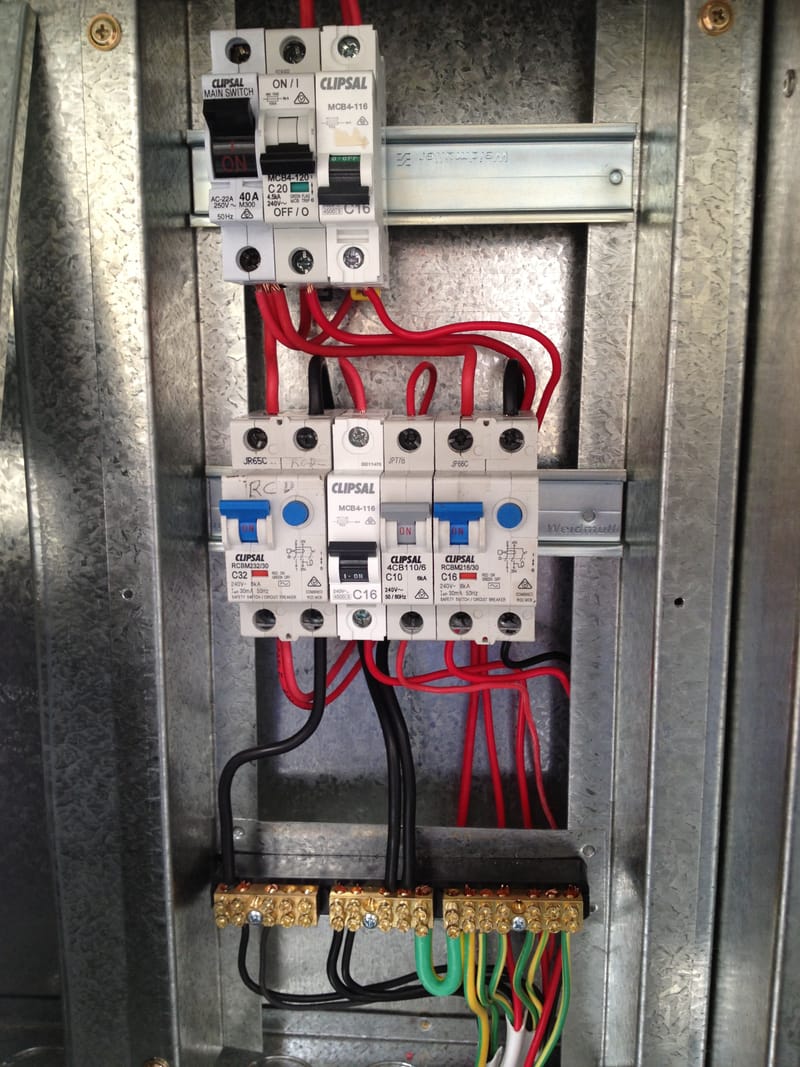

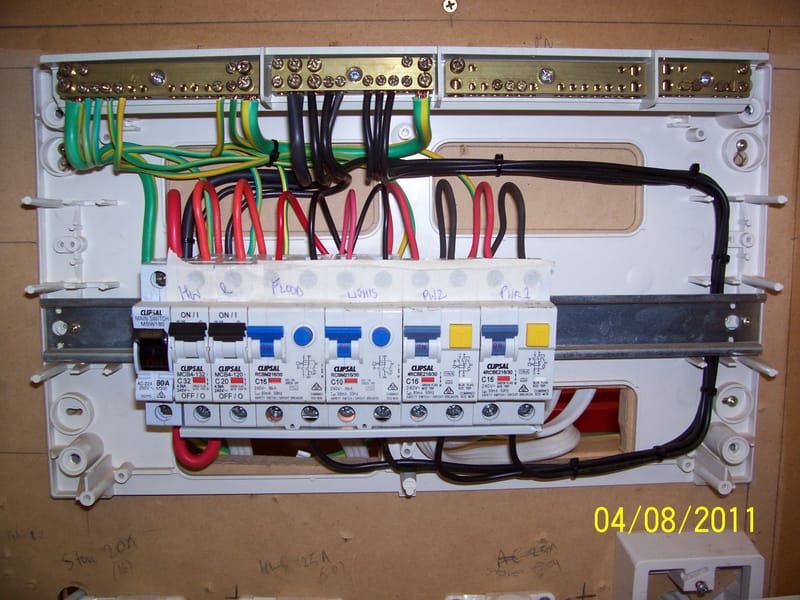

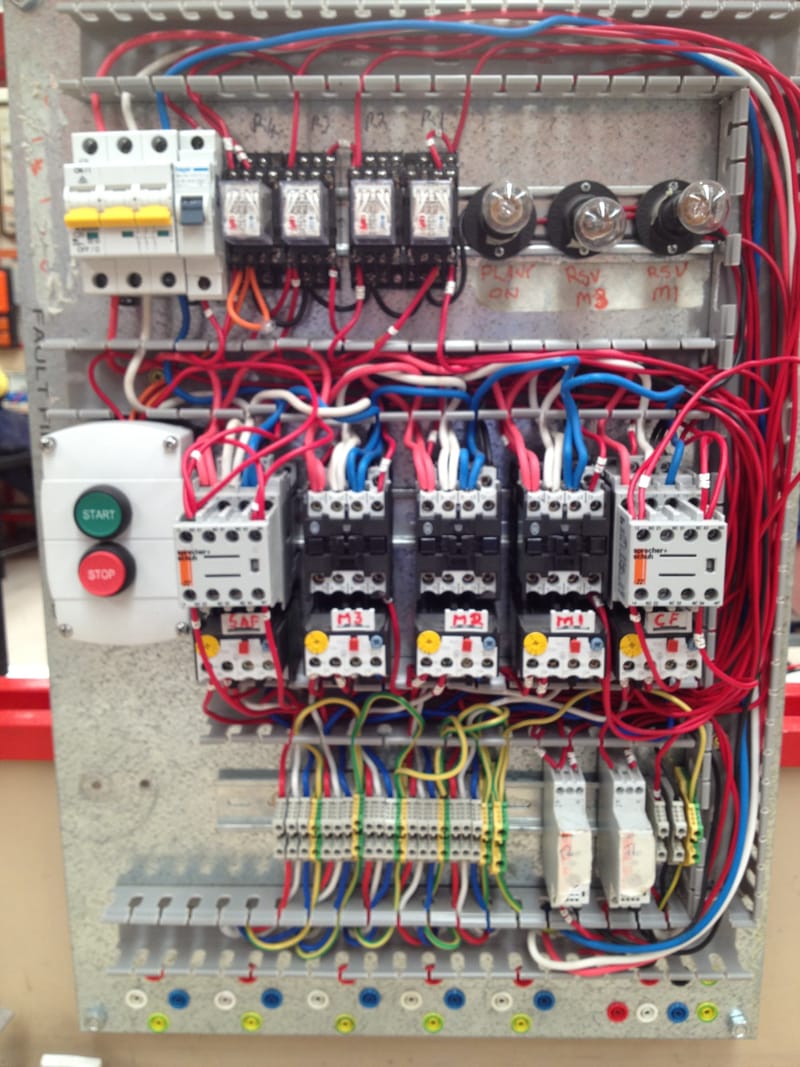

This unit covers the arrangement and termination of circuits, control and protection devices and systems for electrical installations operating at voltages up to 1,000 V a.c. or 1,500 V d.c. It encompass knowledge and application of schemes for protection of persons and property, correct functioning, ensuring compatibility with the supply, arranging installation into circuits and selecting and arranging switchgear/controlgear and protective devices to meet compliance requirements and documenting arrangement decisions.

Read MoreThis unit covers identifying occupational health and safety hazard and risks and documenting control measures. It encompasses identifying workplace hazards, assigning levels of risk, developing control measures to eliminate and/or mitigate risks, reviewing risk control measures and maintaining documentation of hazards, risk control measures and their application in accordance with compliance procedures.

Read MoreThis unit covers ascertaining correct operation of single and three phase low voltage electrical apparatus and circuits and solving circuit problems as they apply to servicing, fault finding, installation and compliance work functions. It encompasses safe working practices, apparatus circuit arrangements, issues related to operation, characteristics and protection and solutions to apparatus/circuit problems derived from calculated and measured parameters.

Read MoreThis unit covers trouble-shooting and repairing faults in electrical apparatus and interconnecting circuits and equipment operating at voltages up to 1,000 V a.c. or 1,500 V d.c. It encompasses working safely, reading circuit diagrams, sketching diagrams from traced wiring, logically applying fault finding procedures, conducting repairs and completing the necessary service documentation.

Read MoreThis unit involves the skills and knowledge required to identify, shut down and restart systems with alternate supplies.It includes identifying the system configuration, working safely with electricity generation systems and inverters, identifying hazards and controlling the associated risks, isolation and testing for de-energisation, reinstating the system after isolation, and completing relevant documentation.

Read MoreSTAGE 5

This unit covers selecting wiring systems and cables for electrical installations operating at voltages up to 1,000V a.c. or 1,500 V d.c. It encompass knowledge and application of wiring systems and cable types, selecting wiring system compatible with the installation conditions, selecting cables that comply with required current-carrying capacity and voltage drop and earth fault-loop impedance limitations, coordination between protective devices and conductors and documenting selection decisions

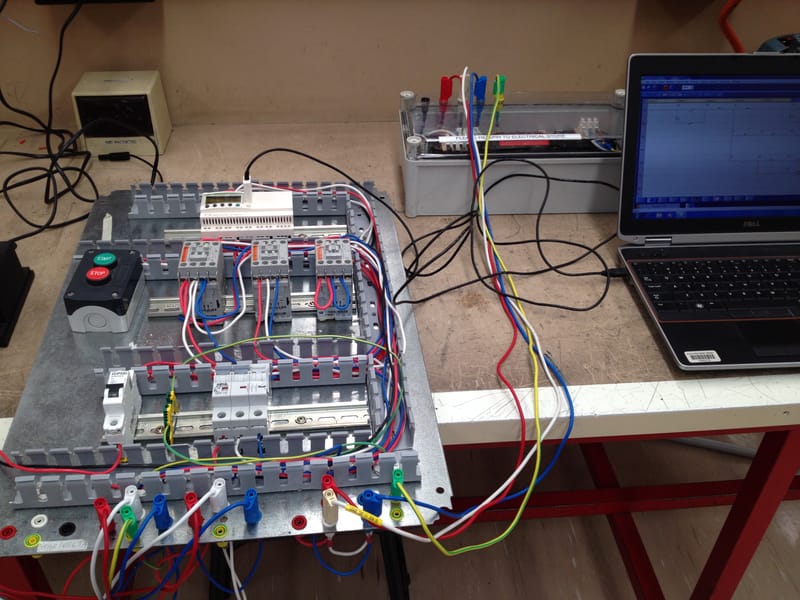

Read MoreThis unit covers developing, connecting and functionally testing electrical power and control circuits that perform specific control functions. It encompasses working safely; developing schematic/ladder diagrams and converting them to wiring diagrams; selecting and connecting contactors and control devices to perform a specific function.

Read MoreSTAGE 6

This unit covers the installation and maintenance of telecommunications cabling in buildings and premises. It encompasses working safely and to Australian Communications and Media Authority's ‘Open’ Cabling Provider Rule, installing multiple telephone line, multi-pair cables, backbone cabling, terminating in socket outlets, termination modules and distributors, testing and compliance checks and completing cabling documentation.

Read MoreThis qualification provides competencies to manufacture, fit, assemble, erect, operate, test, fault find, alter, repair electrical equipment and includes electrical wiring work only if that work is associated with assembling, maintaining, terminating or altering the wiring between electrical components within a plant or machinery. An electrical fitter is not authorised to install any electrical wiring systems within an electrical installation as prescribed by definitions contained in AS/NZS 3000. Electrical equipment means any appliance, article, accessory, wire, fitting, cable, conduit or apparatus that generates, uses, conveys or controls (or that is intended to generate, use, convey or control) electricity above extra low voltage.

Read MoreSTAGE 7

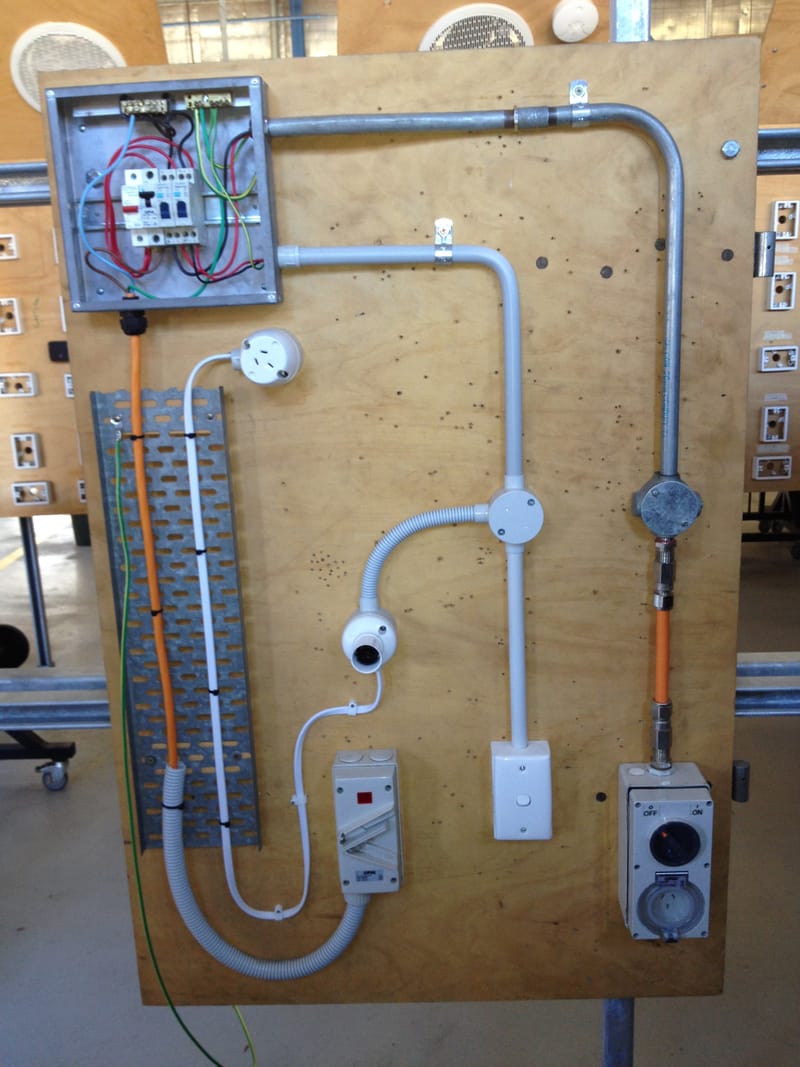

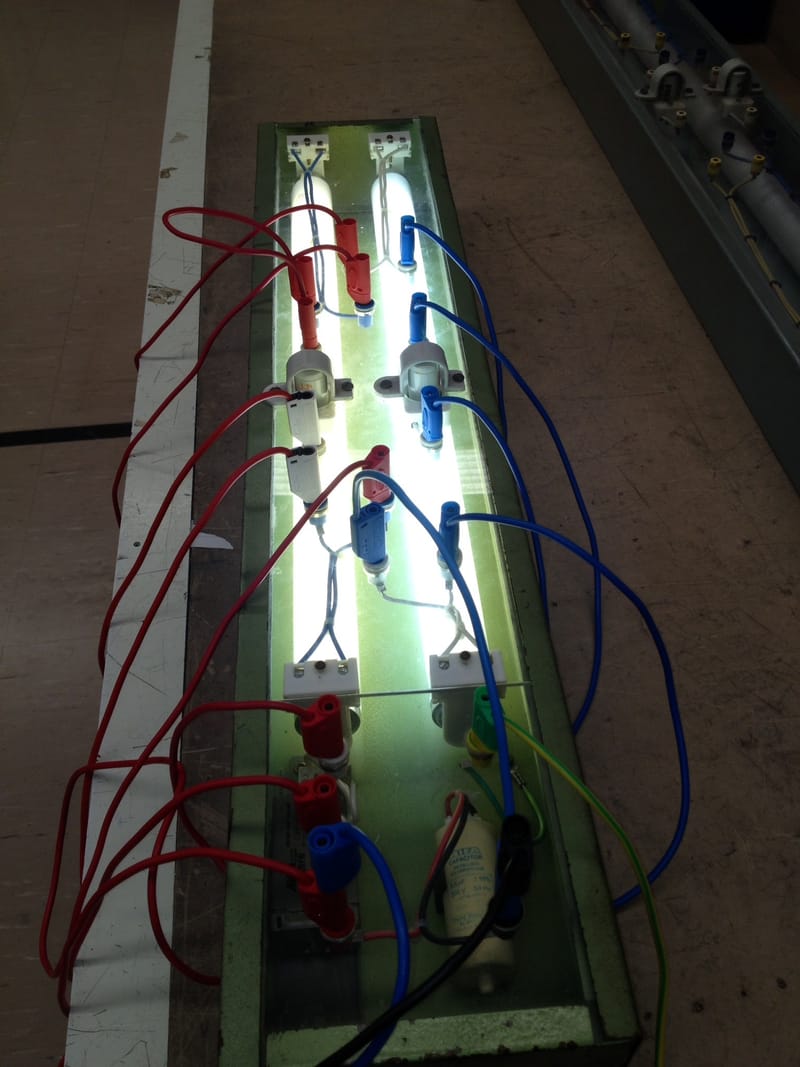

This unit covers the installation in building and premises of wiring enclosures, cable support systems, cables and accessories and designed to operate at voltages up to 1,000 V a.c. or 1,500 V d.c. It encompasses working safely and to installation standards, routing cables to specified locations, terminating cables and connecting wiring at accessories and completing the necessary installation documentation. This unit covers the installation of appliances protection devices, switchgear, controlgear, switchboards, and accessories designed to operate at voltages up to 1,000 V a.c. or 1,500 V d.c. It encompasses working safely and to installation standards, matching appliances and accessories with that specified, making required circuit connections and completing the necessary installation documentation.

Read MoreSTAGE 8

UEENEEG105A - Verify compliance and functionality of low voltage general electrical installations. This unit covers inspection and testing to verify whether an electrical installation is safe and complies with all requirements. It encompasses working safely, visual inspections and mandatory, optional and functional testing following verification procedures, identifying non-compliance defects and mandatory reporting requirements.

Read MoreUEENEEG199A - Conduct compliance and functional verification of electrical apparatus and existing circuits. This unit covers inspection and testing to verify whether an electrical apparatus and/or existing circuits are safe and complies with all requirements. It encompasses working safely, visual inspections and mandatory, optional and functional testing following verification procedures, identifying non-compliance defects and mandatory reporting requirements.

Read More